The Advantage And Application Of PTFE Gasket And O-rings

Polytetrafluoroethylene, also named PTFE for short, a synthetic polymer material that uses fluorine to replace all hydrogen atoms in polyethylene. This material is resistant to acids, alkali, and various organic solvents, and is almost insoluble in all solvents. At the same time, PTFE has the characteristics of high temperature resistance, and its friction coefficient is extremely low. The specific advantages are as follows:

1. High temperature resistance-The working temperature can reach 250℃.

2. Low temperature resistance- PTFE has good mechanical toughness; even if the temperature drops to -196℃, it can maintain 5% elongation.

3. Corrosion resistance- PTFE is inert to most chemicals and solvents, and can withstand strong acids and alkali, water and various organic solvents.

4. Weather resistance- PTFE has the best aging life in plastics.

5. High lubrication- PTFE is the lowest friction coefficient of solid materials.

6. No adhesion- PTFE is the smallest surface tension among solid materials, and does not adhere to anything.

7. Non-toxic- PTFE have physiological inertness, as an artificial blood vessel and organ implanted in the body for a long time without adverse reactions.

8. Electrical insulation- PTFE can resist 1500 volts high voltage.

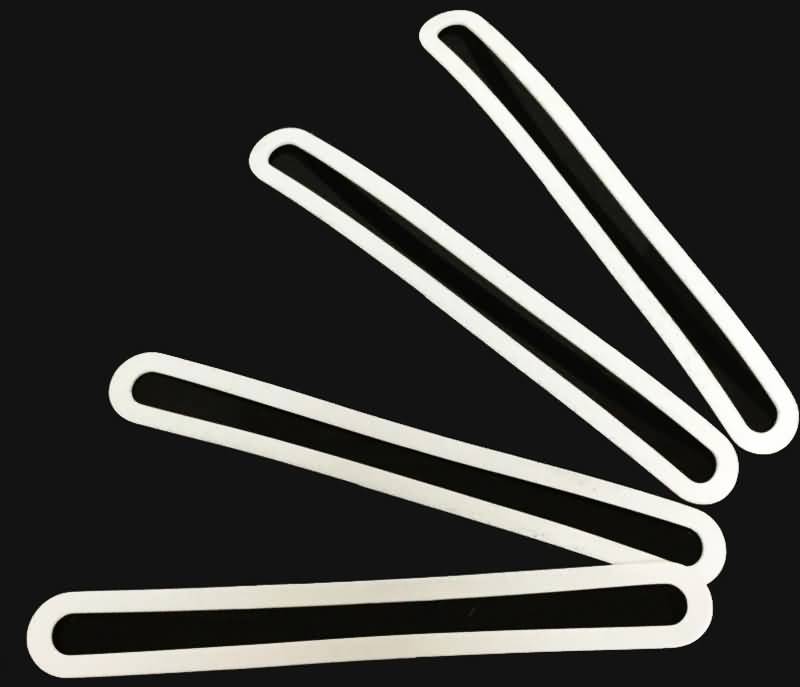

PTFE can be used as a gasket because of its excellent performance.The advantages are as follows:

1. Excellent heat and corrosion resistance

As rubber, glass, metal alloys and other materials have defects in corrosion resistance, it is difficult to meet the harsh conditions of temperature, pressure and chemical media coexistence environment, the resulting losses are quite amazing. OVICTOR PTFE gasket has become the main corrosion-resistant material in the petroleum, chemical, textile and other industries due to its excellent corrosion resistance. Its specific applications include: conveying pipes, exhaust pipes, steam pipes, high-pressure oil pipes of steel rolling mills, aircraft hydraulic systems and cold-pressing systems, distillation towers, heat exchangers, kettles, towers, tanks Lining, valves and other chemical equipment.

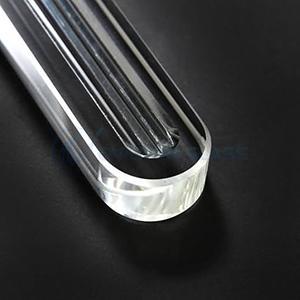

The PTFE gasket material has the characteristics of corrosion resistance, aging resistance, low friction coefficient, non-stickiness, wide temperature resistance range, and good elasticity, making it very suitable for the manufacture of seals with high corrosion resistance requirements and service temperatures exceeding 100°C . The performance of the seal has a great influence on the efficiency and performance of the entire machine and equipment. Such as machinery, heat exchangers, high pressure vessels, large diameter vessels, valves, pumps, grooved flange seals, glass reactors, flat flanges, large diameter flange seals, shafts, piston rods, valve rods, Seals of tie rods, etc.

2. Low friction performance

Because the friction part of some equipment is not suitable for lubrication, such as the occasions where the lubricating grease will be dissolved by the solvent and become invalid, or the products in the industrial fields such as papermaking, pharmaceuticals, food, textiles, etc. need to avoid lubricating oil contamination, this makes the filled PTFE material become The most ideal material for mechanical equipment parts without oil lubrication (direct load). This is because the friction coefficient of Bird's sealing material is the lowest among known solid materials. Its specific uses include bearings for chemical equipment, papermaking machinery, agricultural machinery, as piston rings, machine tool rails, guide rings; widely used in civil engineering projects as bridges, tunnels, steel structure roof trusses, large chemical pipelines, storage tanks Support sliding block, and used as bridge bracket and bridge swivel.

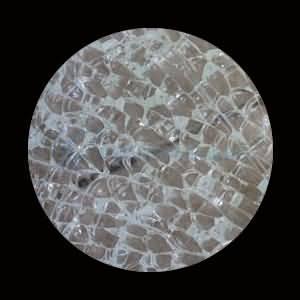

Because of its unique properties, PTFE gaskets have been widely used in industrial and marine operations such as chemical, petroleum, textile, food, paper, medicine, electronics and machinery. OVICTOR PTFE gasket and PTFE o-ring is usually used as a seal of sight glass and level gauge.