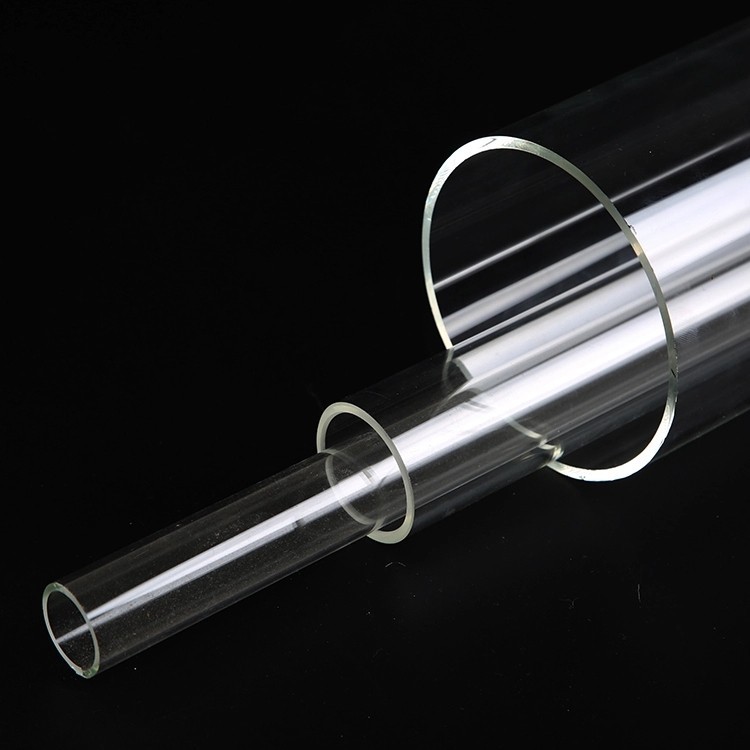

Description

Borosilicate Glass Tube is a type of glass with silica and boron trioxide as the main glass-forming constituents. Borosilicate glass tubes are known for having very low coefficients of thermal expansion (3.3 × 10−6 K−1 at 20 °C), making them more resistant to thermal shock than any other common glass. Borosilicate glass tube is usually used in tubular level gauge for high temperature and pressure resistance, which is also known as tubular gauge glass, pyrex glass tube.

Physical Data of 3.3 Borosilicate GlassTube

|

No. |

Physics Performance |

Numerical Value |

Unit |

|

1 |

Medium coefficient of linear expansion α20/300 acc.To DIN 52328 |

3.3 ± 0.1 |

10-6K-1 |

|

2 |

Transformation Temperature |

525 ± 15 |

Deg.C |

|

3 |

Upper annealing temperature |

560 ± 10 |

Deg.C |

|

4 |

Softening point |

820 ± 10 |

Deg.C |

|

5 |

Working temperature |

260 ± 20 |

Deg.C |

|

6 |

Maximum short-time working temperature |

500 |

Deg.C |

|

7 |

20 degree Celsius Density ρ |

2.23 ± 0.02 |

g/cm3 |

|

8 |

Modulus of elasticity E |

64 |

103 N/mm2 |

|

9 |

Poisson's ratio |

0.20 |

1 |

|

10 |

Thermal productivity(20Deg.C-100Deg.C) |

1.2 |

W/m2K |

|

11 |

Temperature for the specific electrical resistance of 108Ω·cm(DIN52326)tk 100 |

250 |

Deg.C |

|

12 |

Stress-optical constant(DIN52314)K |

4.0 |

10-6mm2/N |

Chemical Data of 3.3 Borosilicate GlassTube

|

Composition |

SiO2 |

B2O3 |

Na2O + K2O |

Al2O3 |

|

approx.weight % |

81 |

13 |

4 |

2 |

|

Water resistance to ISO720 |

1 |

|||

|

Water resistance to European Pharmacopoeia |

1 |

|||

|

Water resistance to USP23 |

1 |

|||

|

Acid resistance Class(DIN12116) |

1 |

|||

|

Alkali resistance Class(ISO695) |

2 |

|||