Description

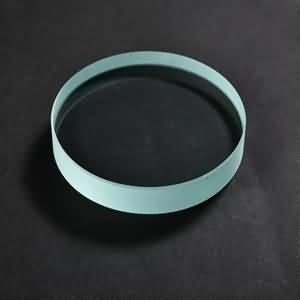

The thermal shock resistance of transparent gauge glass is as high as 230 ° C, which makes the transparent gauge glass as an safety observation window with sudden temperature change in the application environment still stable without fragmentation. Transparent gauge glass is an ideal part as level indicators and for visual control of flows in pipes, tanks, and containers.

Transparent gauge glass has higher pressure resistance characteristics than reflex gauge glass, and a mica shield can be installed on the flat inner surface to isolate the alkaline components in the fluid and prevent it from corrosion.

Main Technical Data

| Working Conditions | Max Operating Temperature | Max Operating Pressue | |||

| °C | °F | bar | Mpa | psi | |

| Saturated steam or hot water in direct contact with reflex or transparent gauge glass | 243 | 470 | 35 | 3.5 | 500 |

| Saturated steam or hot water in contact with flat gauge glasses protected with mica | 320 | 608 | 103 | 10.3 | 1500 |

| Non-corrosive, non-steam service and no technically significant glass attack, with reflex or transparent gauge glass | 38 | 100 | 280 | 28 | 4000 |

| Transparent gauge glass in contact with medias with no technically significant glass attack | 38 | 100 | 345 | 34.5 | 5000 |

| High pressure transparent gauge glass in special gauges | 38 | 100 | 414 | 41.4 | 6000 |

Size and Dimentions

*All size unit in mm

Type A

No

L

B

S

Roman No

Size

Part No

0

95

30

17

-

95X30X17

OVFA00

1

115

30

17

I

115X30X17

OVFA01

2

140

30

17

II

140X30X17

OVFA02

3

165

30

17

III

165X30X17

OVFA03

4

190

30

17

IV

190X30X17

OVFA04

5

220

30

17

V

220X30X17

OVFA05

6

250

30

17

VI

250X30X17

OVFA06

7

280

30

17

VII

280X30X17

OVFA07

8

320

30

17

VIII

320X30X17

OVFA08

9

340

30

17

IX

340X30X17

OVFA09

10

370

30

17

X

370X30X17

OVFA10

11

400

30

17

XI

400X30X17

OVFA11

Type B

No

L

B

S*

Roman No

Size

Part No

0

95

34

17

-

95X34X17

OVFB00

1

115

34

17

I

115X34X17

OVFB01

2

140

34

17

II

140X34X17

OVFB02

3

165

34

17

III

165X34X17

OVFB03

4

190

34

17

IV

190X34X17

OVFB04

5

220

34

17

V

220X34X17

OVFB05

6

250

34

17

VI

250X34X17

OVFB06

7

280

34

17

VII

280X34X17

OVFB07

8

320

34

17

VIII

320X34X17

OVFB08

9

340

34

17

IX

340X34X17

OVFB09

10

370

34

17

X

370X34X17

OVFB10

11

400

34

17

XI

400X34X17

OVFB11

* S can be 17.5mm for high pressure purpose, Part No format is OVFB0**X

Type H

No

L

B

S

Roman No

Size

Part No

0

95

34

22

-

95X34X22

OVFH00

1

115

34

22

I

115X34X22

OVFH01

2

140

34

22

II

140X34X22

OVFH02

3

165

34

22

III

165X34X22

OVFH03

4

190

34

22

IV

190X34X22

OVFH04

5

220

34

22

V

220X34X22

OVFH05

6

250

34

22

VI

250X34X22

OVFH06

7

280

34

22

VII

280X34X22

OVFH07

8

320

34

22

VIII

320X34X22

OVFH08

9

340

34

22

IX

340X34X22

OVFH09

10

370

34

22

X

370X34X22

OVFH10

11

400

34

22

XI

400X34X22

OVFH11

As an industrial equipment operator, you know the importance of keeping an eye on liquid levels. Order this flat gauge glass online and get a crystal-clear view into your processes thanks to its:

Durable and cheap transparent level gauge

- Reliability. Our DIN 7081 glass boasts unparalleled reliability. Made of the advanced borosilicate glass variety, it’s built to last through the most demanding applications.

- Ease-to-read properties. It provides an unobstructed view of your tank’s contents and lets you keep a close eye on flows and fluid levels at a glance, even from far away.

- Low maintenance. You won’t need to perform routine maintenance or part replacements. Buy this flat sight glass and expect years of enduring service.

- Safety. It prevents pressure buildup and minimizes the chance of dangerous spills or releases.

- Cost-effectiveness. This glass costs less than complex electronic sensors and doesn’t require expensive control systems or instrumentation.

As a transparent-type level gauge manufacturer, we utilize the latest real-life testing technologies to engineer the DIN 7081 glass with exceptional clarity, strength, and chemical resistance. Owning to the use of specialized glass composition and our meticulous production process, we can create level gauges for any industrial application.

Applications of the transparent gauge glass

This gauge is ideal for securely and accurately keeping track of fluid levels in harsh environments. The main sectors that use this glass type include:

- Chemical processing. Borosilicate glass 4.0 makes this piece suitable for extreme temperatures and pressures, as well as highly acidic or caustic substances. You can purchase the flat glass for the level gauge to let your operators instantly see if a reaction is occurring or if a substance needs replenishment.

- Pharmaceutical production. Our high-purity gauge glass meets strict sanitation standards and provides a clear view of active pharmaceutical ingredients, solutions, and mixtures in a sterile environment.

- Food & Beverage industry. From craft breweries to industrial food production, the transparent sight glass for sale is an easy way to check levels, see if a vessel needs refilling, or if a product has fully drained or dispensed.

- Energy generation. Does your power plant rely on gauges to monitor water in steam boilers and other equipment? With this glass, you can check the levels from a distance and ensure the boilers are functioning correctly.

Additionally, you can count on Ovictor Glass as your flat-type glass level gauge supplier if you are working on a project in metal finishing, waste/water treatment, and other industries. Send us an inquiry to discuss your specs with our experts.