Description

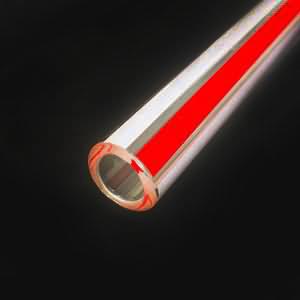

Borosilicate Glass Tube is a type of glass with silica and boron trioxide as the main glass-forming constituents. Borosilicate glass tubes are known for having very low coefficients of thermal expansion (3.3 × 10−6 K−1 at 20 °C), making them more resistant to thermal shock than any other common glass.

Physical Data of 3.3 Borosilicate GlassTube

|

No. |

Physics Performance |

Numerical Value |

Unit |

|

1 |

Medium coefficient of linear expansion α20/300 acc.To DIN 52328 |

3.3 ± 0.1 |

10-6K-1 |

|

2 |

Transformation Temperature |

525 ± 15 |

Deg.C |

|

3 |

Upper annealing temperature |

560 ± 10 |

Deg.C |

|

4 |

Softening point |

820 ± 10 |

Deg.C |

|

5 |

Max Working temperature |

400± 20 |

Deg.C |

|

6 |

Maximum short-time working temperature |

500 |

Deg.C |

|

7 |

20 degree Celsius Density ρ |

2.23 ± 0.02 |

g/cm3 |

|

8 |

Modulus of elasticity E |

64 |

103 N/mm2 |

|

9 |

Poisson's ratio |

0.20 |

1 |

|

10 |

Thermal productivity(20Deg.C-100Deg.C) |

1.2 |

W/m2K |

|

11 |

Temperature for the specific electrical resistance of 108Ω·cm(DIN52326)tk 100 |

250 |

Deg.C |

|

12 |

Stress-optical constant(DIN52314)K |

4.0 |

10-6mm2/N |

Chemical Data of 3.3 Borosilicate GlassTube

|

Composition |

SiO2 |

B2O3 |

Na2O + K2O |

Al2O3 |

|

approx.weight % |

81 |

13 |

4 |

2 |

|

Water resistance to ISO720 |

1 |

|||

|

Water resistance to European Pharmacopoeia |

1 |

|||

|

Water resistance to USP23 |

1 |

|||

|

Acid resistance Class(DIN12116) |

1 |

|||

|

Alkali resistance Class(ISO695) |

2 |

|||